Open Essex

Innovation

How Rapid Manufacturing is Revolutionizing Low Volume Manufacturing

Many companies have found that manufacturing in low volume has always been expensive and complicated. Yet, the world of manufacturing low-volume production is undergoing a major transformation with the arrival of new manufacturing techniques that are rapid. The rapid manufacturing process changes the manner the products are made by giving businesses the ability to work with ability to adapt, speed and efficiency necessary to survive in the current competitive market.

What is Rapid Manufacturing?

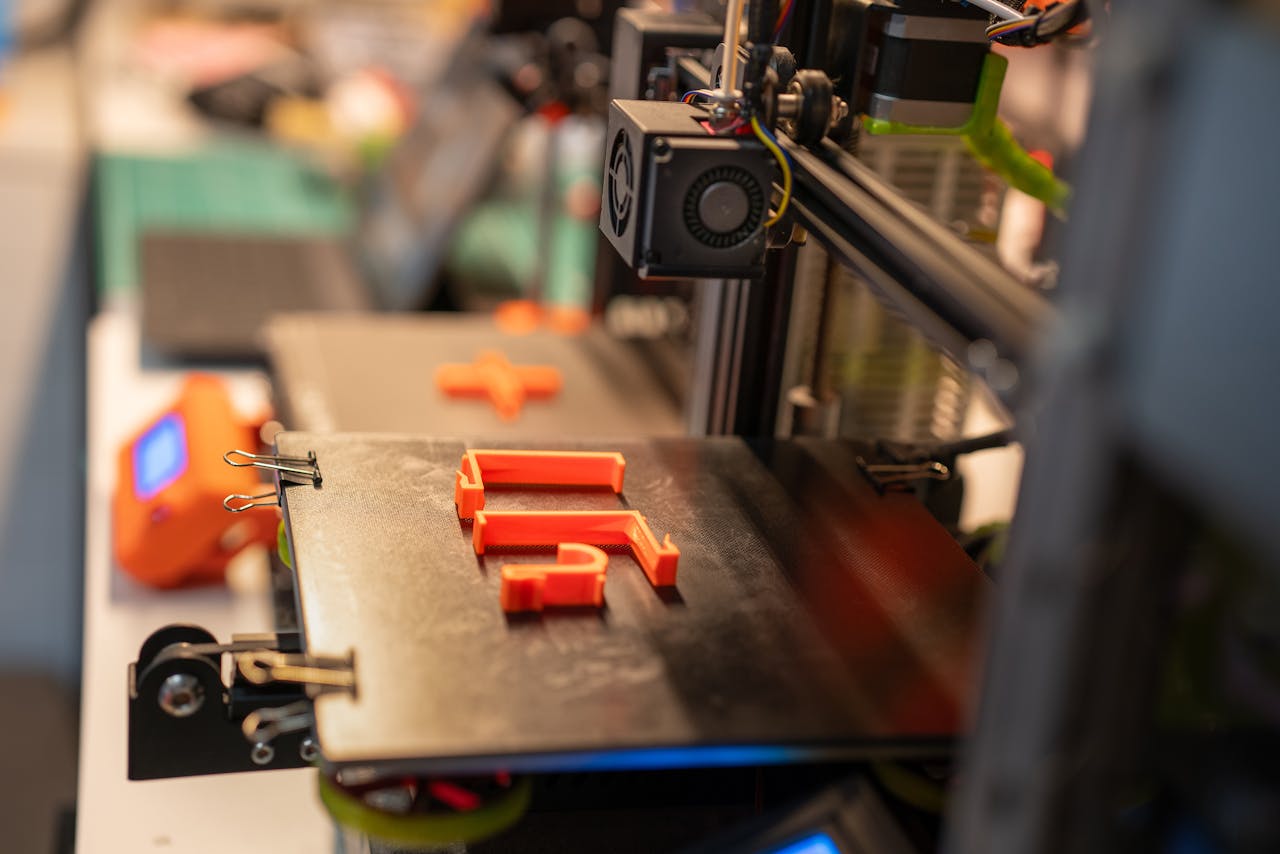

Rapid manufacturing is an advanced manufacturing method that utilizes advanced techniques like 3D printing CNC machining, and injection molding to make tiny quantities of customized components or items faster and more cost-effective. Contrary to conventional methods, that require costly tools necessary, along with lengthy durations and long lead times, rapid prototyping allows businesses to develop their concepts quickly as well as produce small amounts and then get their products to market faster than before.

Advantages of Rapid Manufacturing

The rapid manufacturing process has many advantages for companies who want to make products in lower quantities. A few of the benefits that come with quick manufacturing are:

Acceleration: This technology enables producers to build prototypes, as well as smaller batch sizes at a faster rate, thus cutting down time-to-market as well as enhancing design cycles.

Cost savings: With the elimination of the need for expensive tools and the reduction of wasted raw materials Rapid prototyping has the potential to dramatically cut production costs in low quantity production requirements.

Prototyping speedy can also allow the manufacture of distinctive and high-quality products, helping businesses to meet the specific needs or preferences of customers.

Flexible: This method permits the easy modifications of designs in addition to iterating prototypes of different products, in addition to other modifications made throughout the procedure.

Applications of Rapid Manufacturing

Rapid manufacturing is being widely adopted across a variety of industries for the production of low volume parts and products. Some of the key applications of rapid manufacturing include:

Industry

Application

Automotive

Prototyping of new vehicle components

Medical

Customized medical devices and implants

Aerospace

Production of lightweight aircraft components

Consumer Electronics

Customized smartphone accessories

In many companies, production at a low volume manufacturing was an expensive and complex venture. Yet, the world of production with low volumes has seen a dramatic transformation with the advent of new manufacturing techniques that are rapid. The rapid manufacturing process changes the manner the products are made by giving businesses the ability to work with ability to adapt, speed and efficiency needed to thrive in the rapidly changing market.

What is Rapid Manufacturing?

Rapid manufacturing is a new manufacturing method that utilizes advanced techniques like 3D printing CNC machining, as well as injection molding, to create smaller quantities of custom-designed items or parts quicker and at a lower cost. Contrary to conventional methods, which require expensive tools required, as well as lengthy time-to-market Rapid prototyping allows companies to test their ideas quickly and produce in smaller quantities and bring their product to market faster than they have ever.

Advantages of Rapid Manufacturing

The rapid manufacturing process has many advantages for companies who want to make goods in lesser quantities. A few of the benefits that come with quick manufacturing are:

Acceleration: This technology permits companies to develop prototypes, as well as smaller batch sizes at a faster rate, thus decreasing time to market and improving product design cycles.

Cost savings: With the elimination of the need for expensive tools and the reduction of wasted raw materials rapid prototyping has the potential to dramatically cut production costs in low quantities of production.

Prototyping speedy can also allow the manufacture of distinctive and extremely customized products, thereby helping businesses to meet the specific needs or requirements of clients.

Flexibility: This process allows simple modifications to designs, in addition to iterating prototypes of different products, in addition to different changes that are made in the course of development.